Application of Salt Fog Test Chamber:

Salt Fog Test Chamber is particularly useful for assessing the durability of materials and coatings against various corrosion mechanisms, such as general corrosion, galvanic corrosion, and crevice corrosion. Some of the key applications include: automotive Industry, aerospace and aviation, marine and offshore, construction and infrastructure, electronics and electrical, energy industry.

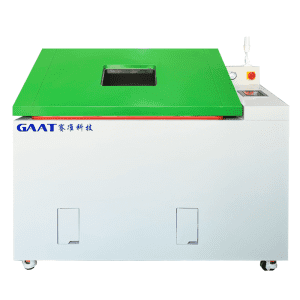

Features:

- Automated Cyclic Control: Advanced software that manages the sequence of corrosion cycles, including salt fog, drying, and humidity, to simulate real-world conditions.

- Temperature and Humidity Regulation: Precise control over temperature and humidity levels to ensure accurate and consistent test results.

- Sample Racks: Adjustable sample racks that can accommodate a variety of test specimen sizes and shapes.

- Data Logging and Reporting: Capabilities to log test data and generate detailed reports for quality assurance and documentation.

- Accelerated Testing: Reduces the time required to assess the corrosion resistance of materials, speeding up the development and quality control processes.

Testing Standards:

DO160 E/F/G ISO14993-2001 ISO16151:2005

GJB 150.11A IEC60068-2-11 IEC 60068-2-52

IEC6008-2-78 GB/T 20854 ISO9227-2006

ASTM B117 ASM B368 GB/T 10587

Technical Parameters

| Model | SZ-1000D、SZ-1600D、SZ-2000D | |

| Inner Size WxHxD (mm) | 1200x800x1000、1600x800x1000、2000x800x1000 | |

| Exterior Size WxHxD (mm) | 2500x1720x1420、2950x1720x1220、3550x1900x1220 | |

| Testing Zone Capacity (not including V shape cover) | 960L、1280L、1600L | |

| Method of Opening Cover | Pneumatic | |

| Inner Chamber Material | Pure Titanium Plate | |

| Temperature Range | 20℃~70℃ | |

| Temperature Control Accuracy | Temperature fluctuation:≤ ±0.5℃ Temperature uniformity:≤ ±2℃ | |

| Humidity Range | 20%~98%RH | |

| Humidity Control Accuracy | Humidity fluctuation:≤ ±2%RH Humidity uniformity:≤ ±3%RH(When RH≥75%); ≤ ±5%RH(When RH<75%) | |

| Spray Volume | 1.0~2.0ml/80cm2/h | |

| Spray Method | Continuous spray, cyclic spray and programmable spray. | |

| Standard configuration | User-friendly touch screen controller with remote control and monitoring software Fixable and moveable casters with leveling function. Test porthole 1pc φ50/100/200mm. V Shape sample holder and O shape sample rack. External salt solution tank with liquid level sensor. Three-color tower light with buzzer to indicate oven operation status. | |

| Safety Features | Over temperature protection for both test chamber and pressure barrel, water leakage protection for both test chamber and pressure barrel, heater dry burn protection, water supply abnormal alarm, water drainage abnormal alarm, earth leakage protection, overload and short-circuit protection, fan motor over-temp protection, compressor over-heat, over-current, over-pressure protection | |

Get A Quote

View More:

Reviews

There are no reviews yet.